Ordinary EPS Sandwich Panel is the abbreviation of exploitable polystyrene board. Apolystyrene foam sheet with a closed cell structure is prepared by heating the exploitable polystyrene beads in a mold after pre-foaming with heating.

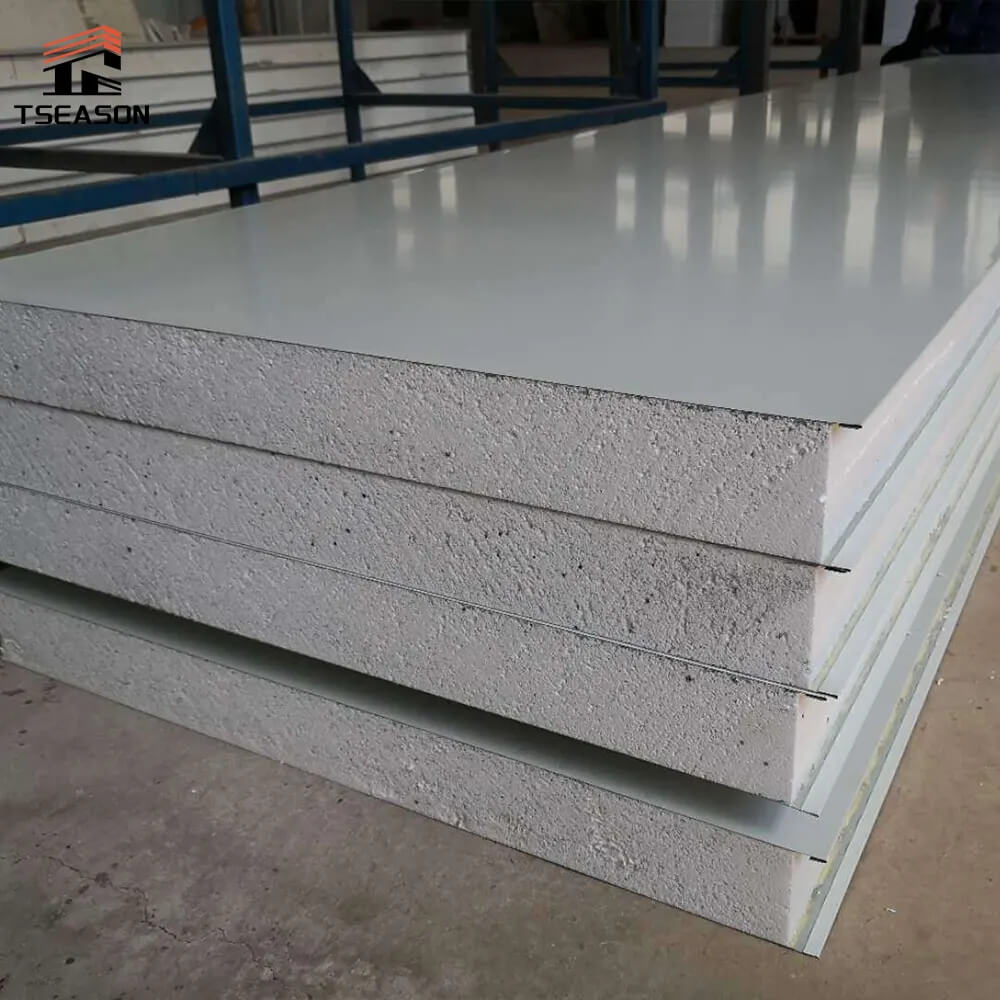

The Tseason EPS wall panel stands out with superior quality, advanced manufacturing, and customizable solutions. Made with premium color-coated steel and high-density EPS foam, our panels deliver outstanding thermal insulation, fire resistance, and durability. Thanks to our automated production lines and strict quality control, every EPS wall panel ensures consistent performance and long service life. Tseason supports fast delivery, flexible sizing, and expert technical support, making us a trusted choice for industrial buildings, cleanrooms, and modular structures.

We understand that every customer has different expectations and needs for EPS panels, so we are committed to providing full support and assistance throughout construction.

Ordinary EPS Sandwich Panel is the abbreviation of exploitable polystyrene board. Apolystyrene foam sheet with a closed cell structure is prepared by heating the exploitable polystyrene beads in a mold after pre-foaming with heating.

Flame retardant EPS board adopts particle fire insulation film technology, the use of copolymerization modification to make EPS monomer particles have the same characteristics of fireproof substances, and the use of microphase composite technology to form a fire insulation film on the surface of each organic particle.so that each particle forms a relatively independent organic particle fire prevention unit.

| Core Material | EPS/ A1 grade non-flammable EPS foam |

| Steel Sheet | Color coated plate/Galvanized plate/ Stainless steel plate |

| Steel Thickness | 0.3-0.6mm Galvanized color drawing steel plate(purification plate special) |

| Standard Thickness | 50mm/75mm/100/150mm |

| Standard Panel Width | 1150 mm |

| Panel Length | Customization |

Regarding structural design, Tseason EPS wall panels adopt a unique tongue-and-groove design, which makes the joints between panels tighter and more stable. At the same time, the surface can be flat or slotted to meet the needs of different application scenarios, while the EPS roof panel adopts a corrugated design, which not only enhances the strength of the panels but also facilitates the smooth drainage of rainwater.