High-Performance Polyurethane Foam Insulation Panels for Cold Storage Builders

In the evolving landscape of cold chain logistics and refrigeration infrastructure, polyurethane foam insulation panels have become the cornerstone of high-efficiency thermal control systems. For cold storage builders and developers seeking unmatched thermal performance, structural integrity, and energy efficiency, polyurethane foam insulation panels from Tseason provide the ideal solution.

These panels are specifically engineered to meet the stringent requirements of cold storage construction, where maintaining consistent internal temperatures and minimizing energy consumption are critical.

What Are Polyurethane Foam Insulation Panels?

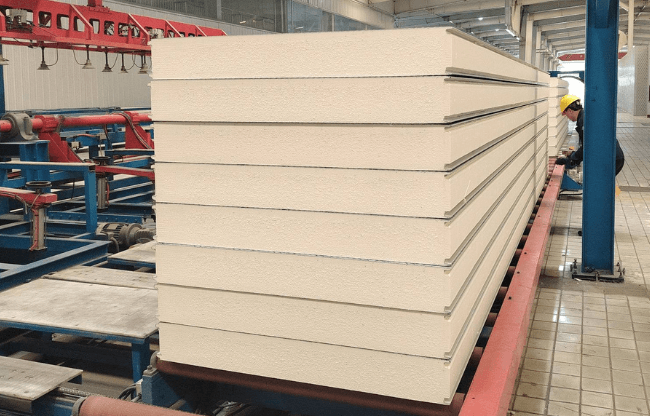

Polyurethane foam insulation panels consist of a rigid polyurethane (PU) foam core sandwiched between two layers of protective steel sheets. The panels act as both insulation and structural components, making them ideal for industrial cold rooms, refrigerated warehouses, and processing plants. Their low thermal conductivity, excellent compressive strength, and moisture resistance make them a top choice for environments that demand constant temperature regulation.

Tseason panels are produced using state-of-the-art OMS high-pressure foaming machines, ensuring uniform cell structure and consistent quality across every square meter.

Key Technical Specifications

| Specification | Value |

|---|---|

| Thermal Conductivity | ≤ 0.022 W/m·K |

| Fire Resistance | Class B1 (China National Standard) |

| Foam Density | ≥ 40 kg/m³ (uniformly foamed by OMS technology) |

| Bonding Strength | ≥ 0.1 MPa |

| Panel Thickness | 50mm / 75mm / 100mm / 120mm / 150mm / 180mm / 200mm / 220mm / 250mm |

| Surface Material | Color-coated steel, stainless steel, or aluminum (customizable) |

| Production Equipment | Imported OMS foaming line and PUMA automatic sandwich panel line |

These parameters ensure reliable long-term performance, even under extreme environmental conditions and frequent temperature fluctuations.

Product Advantages for Cold Storage Applications

- Excellent Thermal Performance

The core PU material has one of the lowest thermal conductivity ratings available. This ensures minimal heat transfer, critical for maintaining the efficiency of refrigeration units. - Precise Fit and Airtight Assembly

Thanks to PUMA's high-speed production line, each panel maintains perfect dimensional accuracy, enabling seamless interlocking and minimizing thermal bridges. - Moisture and Vapor Resistance

PU panels are inherently resistant to moisture infiltration, preserving insulation performance and preventing microbial growth inside the cold room. - Robust Structural Strength

Tseason's panels can withstand high compressive loads and mechanical stress, allowing installation in high-rack cold warehouses or as load-bearing partitions. - Quick Installation and Lightweight Design

The sandwich structure makes the panels light yet rigid, allowing for rapid installation and reducing structural load on buildings. - Reliable Fire Safety (Class B1)

The panels conform to national fire resistance standards for cold storage applications, providing peace of mind for commercial and industrial users. - Sustainable and Eco-Friendly Manufacturing

Tseason uses water-based adhesives and efficient foam systems to lower emissions, supporting carbon-reduction initiatives.

Application Scenarios

Tseason polyurethane foam insulation panels are perfectly suited for:

- Cold storage warehouses

- Blast freezing chambers

- Food processing facilities

- Refrigerated logistics centers

- Cleanrooms and pharmaceutical storage

- Supermarket cold rooms

These environments demand reliable and consistent insulation solutions. Tseason panels ensure the stability, cleanliness, and compliance needed for such operations.

Why Choose Tseason?

- Nearly 30 Years of Industry Expertise

Tseason has delivered quality insulation and building systems for three decades, earning trust across global markets. - Advanced Equipment: OMS and PUMA

We utilize the world's leading OMS high-pressure foaming machines for polyurethane injection and the PUMA automatic line for precise and high-speed panel assembly. - Massive Production Capacity

Our facility delivers over 5 million square meters of sandwich panels annually and 3,000 sets of integrated prefabricated buildings. - Certified Quality Assurance

ISO 9001, ISO 14001, OHSAS 18001, CE, GOST, and SGS certifications ensure compliance with international standards. - Strong Customization and R&D Capabilities

With a team of over 100 engineers and designers, Tseason can tailor solutions for zero-carbon buildings, modular cold rooms, and decorative surfaces. - Rich Global Project Experience

From Middle East cold warehouses to Southeast Asia’s seafood processing plants, our panels perform reliably in demanding international settings.

Contact Us Today

Don't miss this opportunity to upgrade your cold storage facilities with Tseason's polyurethane foam insulation panels. Supply is limited and orders are filling quickly.

Get in touch now to speak with our technical consultants or request a free sample. Let us help you build the next-generation cold storage solution with maximum efficiency and durability.