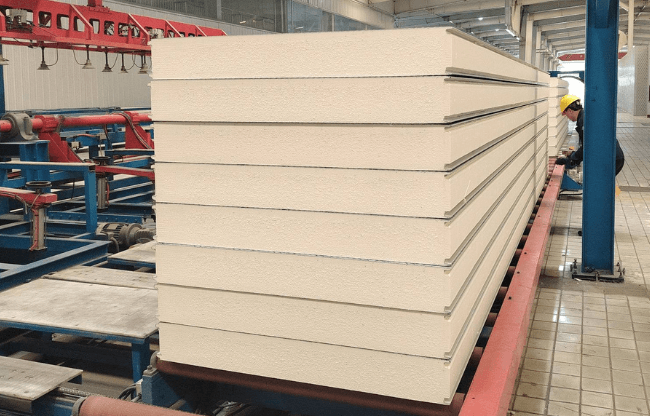

An Upgraded Packing Solution for PU Sandwich Panels

In international construction projects, good products alone don’t guarantee a smooth outcome.

When it comes to PU sandwich panels—especially PU wall panels and PU roof panels—the way they are packed, handled, and unloaded often determines how efficiently a project can move forward once materials arrive on site.

For a recent shipment to Australia, we examined the entire logistics chain in greater detail. After discussing the client’s unloading conditions and site workflow, we completely revamped the packing and loading process. The goal was simple: reduce risk, make unloading easier, and ensure every panel arrives in installation-ready condition after long-distance sea transport.

Why Packing Deserves More Attention Than It Usually Gets

PU sandwich panels are known for their thermal performance and structural reliability. But during transportation, they face challenges that are easy to overlook:

Long sea routes mean constant vibration and repeated handling. Port operations increase the chance of impact and compression. Improper unloading can damage edges, coatings, or joint profiles

That’s why, before this shipment left the factory, we worked closely with the Australian customer. We reviewed their lifting equipment, unloading sequence, and storage plan, then adjusted the packing solution to fit real site conditions—not just shipping requirements.

Heavy-Duty Steel Pallets That Make a Difference on Site

The first major upgrade was replacing standard pallets with custom heavy-duty steel pallets.

These pallets are built to handle the full weight of PU wall panels and PU roof panels without deformation. More importantly, they allow forklifts to lift and move each unit directly at the destination port. That cuts down unloading time and reduces manual handling—two things Australian job sites take seriously when it comes to safety and efficiency.

In practice, this pallet system gives operators better control and significantly lowers the chance of accidental damage during unloading.

Reinforced Steel Edge Protection Where It Matters Most

Panel corners are usually the first areas to suffer during lifting and container loading. To address this, we added custom steel edge protectors to every pack.

These steel bumpers absorb impact during hoisting and positioning inside the container. They protect panel edges from compression and collision, keeping corners clean and straight. For PU roof panels in particular, this matters—a precise edge is essential for proper waterproofing once installed.

Foam Spacers to Keep Panels Stable Over Long Sea Routes

Between each panel bundle, we placed high-density foam spacers. It’s a small addition, but an important one.

These spacers prevent shifting between packs, reduce surface abrasion caused by vibration, and help preserve the panel coating throughout the journey. For shipments to Australia, where transit times are longer, this extra layer of protection helps ensure panels arrive exactly as they left the factory.

High-Strength Strapping for Overall Stability

To lock everything in place, we used high-strength strapping bands around each unit.

The strapping keeps the entire bundle tight during container movement and prevents internal shifting. Combined with the steel pallets and foam spacers, it creates a stable, integrated packing system designed specifically for ocean freight conditions.

Pre-Installed Tow Ropes for Smoother Handling After Arrival

To make unloading easier once the container is opened, we also added pre-installed tow ropes.

This allows site teams to move panel packs smoothly after unloading, without constantly repositioning lifting equipment. It’s a small detail, but in real-world site operations, details like this often save time and reduce unnecessary handling.

Clear Labels and Packing Lists to Avoid Costly Mistakes

Each package is delivered with clear external labels and detailed packing lists. Specifications and quantities are easy to identify at a glance.

This helps port operators and warehouse teams handle the cargo correctly, reducing errors, re-checks, and delays that can ripple through a project schedule.

Smart Container Layout with Over 95% Space Utilization

Inside the container, the loading layout was carefully planned to reach over 95% space utilization.

This approach improves shipping efficiency, lowers logistics cost per square meter of panels, and ensures balanced loading to avoid internal movement. Every placement decision was made with both safety and cost control in mind.

Controlled Loading from Start to Finish

During the final loading stage, two forklifts worked together in coordination. Hoisting was done slowly and steadily, with each movement controlled to avoid sudden impact.

This last step ensures that every PU wall panel and PU roof panel leaves the factory properly protected—no shortcuts taken.

More Than Shipping: Thinking Beyond the Container Door

Reliable delivery doesn’t stop when the container doors are sealed. It continues through arrival, unloading, and installation on site.

For this Australian project, the upgraded packing solution reflects a broader mindset: protecting product quality, supporting on-site operations, and reducing hidden logistics risks that can affect project timelines.

If you’re planning a project that uses PU sandwich panels for walls or roofs, and you want packaging that matches the quality of the panels themselves, we’re ready to talk.

👉 Contact Tseason to discuss a safer, project-ready packing and delivery solution for PU sandwich panels.