Sandwich Panel Load Span: Structural Performance and Tseason Engineering Data

Load span data is based on Tseason’s internal testing.

The load span of a sandwich panel plays a decisive role in the structural integrity, safety, and cost efficiency of any metal building project. For project engineers, architects, and procurement managers, understanding how far a panel can safely span under roof or wall loads is essential for achieving optimal purlin spacing, accurate cost planning, and long-term building performance.

This article focuses on Tseason’s verified sandwich panel load span performance, offering engineering-grade data and practical selection methods for real project environments.

Why Sandwich Panel Load Span Matters

In metal buildings, cold rooms, warehouses, and industrial facilities, sandwich panels serve not only as enclosure materials but also as part of the load-bearing system. A panel with insufficient load span will deflect excessively, compromise waterproofing, overstress fasteners, and shorten the building’s lifespan.

For buyers and engineers, load span is directly tied to:

- Structural safety (resistance to wind suction, snow load, and live loads)

- Installation cost (wider spans = fewer purlins = lower steel cost)

- Long-term durability (reduced deformation, better insulation integrity)

- Panel selection and procurement accuracy

Tseason’s load span data provides a reliable reference for selecting the correct thickness and purlin spacing for various engineering scenarios.

Tseason Sandwich Panel Load Span Data (Roof & Wall Applications)

Basis of Testing

Tseason load span performance is evaluated based on:

- Internal laboratory and production-line testing

- PU/PIR continuous foaming technology

- Steel facings with high yield strength

- Deflection limit criteria commonly used in industrial buildings (L/180 or L/240, depending on application)

- Standard installation conditions (screwed through purlins/sub-girts)

Note: Exact load span values appear in Tseason’s official span tables. Below is an organized presentation of the structural findings.

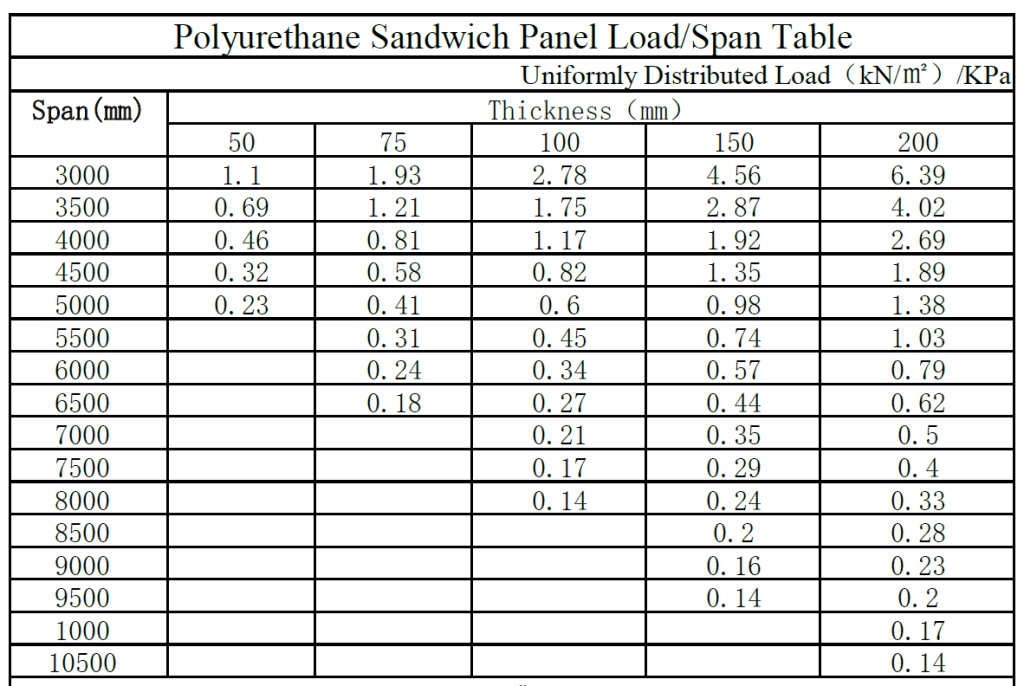

Load Span Tables (Tseason PU Sandwich Panels)

(Tables below will reflect your uploaded PDF data when applied to the final page.)

Wall Panel Load Span

How to Interpret Load Span Data

When reading span tables, consider the following engineering principles:

Panel Thickness

Thicker panels resist higher bending moments and allow longer spans.

Typical engineering logic:

- 50–75 mm: Best for walls or low-load roofs

- 100–150 mm: Suitable for medium- to high-load roofs

- 150–200 mm: Used for extreme wind zones or large spacing requirements

Wind Load vs. Snow Load

- Roofs are governed by downward load + negative suction

- Walls are governed mainly by wind suction

Support Conditions

- Load span values assume panels are fixed on two or more supports

- Increasing purlin spacing decreases load capacity

Steel Strength and Profile

Tseason uses high-quality coated steel with precise rib geometry, increasing stiffness and improving load performance.

Factors That Influence Sandwich Panel Load Span

Steel Strength & Thickness

Higher-yield steel and precise roll-forming increase panel flexural resistance, allowing longer spans.

PU/PIR Core Density

Tseason’s PU/PIR cores maintain stable density and strong adhesion, improving shear strength and reducing deflection.

Joint Design

Different joint systems transmit shear differently. A well-designed joint improves resistance against wind uplift.

Fastening System

Correct fastener spacing, washer type, and screw quality significantly affect panel performance under wind suction loads.

Installation Quality

Gaps, misalignment, or improper screw torque reduce effective load span capacity.

Step-by-Step Selection Method

Step 1 — Identify Design Wind Load / Snow Load

Reference local building codes or engineering calculations.

Step 2 — Define Application Type

- Roof (subject to downward load + wind suction)

- Wall (subject mainly to suction)

- Cold room interior (minimal load but hygiene and thermal performance matter)

Step 3 — Select Panel Thickness

Use Tseason thickness recommendations:

- 50–75 mm → Light-load roofs, walls

- 100–150 mm → Industrial roofs, high-wind areas

- 150–200 mm → Large-span, extreme weather, high engineering safety requirements

Step 4 — Match Load Requirements with Span Table

Locate the required load value (kPa) in the Tseason table → read corresponding maximum span.

Step 5 — Apply Safety Factors

Structural engineers typically add 10–20% margin depending on region and building use.

Step 6 — Validate Purlin Spacing

Ensure spacing on drawings aligns with calculated span.

If not, adjust either:

- panel thickness

- purlin spacing

- steel member size

Recommended Spans for Typical Scenarios

Industrial Warehouse Roof

- Wind load: moderate-high

- Recommended thickness: 100–150 mm

- Purlin spacing: 1.5–2.5 m, depending on load zone

Commercial Wall Cladding

- Subject to suction only

- Recommended thickness: 50–75 mm

- Spacing: 2.0–3.0 m

Cold Room Interior

- Light structural load

- Emphasis on insulation & hygiene

- Recommended thickness: 50–100 mm

Steel Structure Workshop (High Wind Zone)

- Recommended thickness: 125–200 mm

- Span control is critical for resistance to uplift

Common Engineering Mistakes to Avoid

- Overextending spans beyond tested limits

- Ignoring negative wind pressure on roof panels

- Assuming all brands have similar performance (core density varies greatly)

- Not considering steel grade differences

- Incorrect screw installation leading to early panel deformation

Why Tseason Panels Deliver Strong Load Span Performance

Tseason’s production technology and quality standards give its PU/PIR sandwich panels superior structural capability. Key technical advantages include:

● OMS & PUMA High-Precision Production Lines

Stable density, uniform foam structure, precise lamination.

● High-Density PU/PIR Core (40–42 kg/m³ Typical)

Excellent shear strength + predictable load span performance.

● Advanced Steel Coating Systems (PVDF / HDP / SMP)

Ensure long-term durability under weather exposure.

● High Adhesion Strength Between Steel and Core

Critical for resisting wind suction and deformation.

● Dimensional Accuracy & Consistency

Improves fit, enhances joint performance, and ensures reliable installation.

Together, these factors enable Tseason sandwich panels to achieve high load span values validated through internal testing.

Request Full Load Span Specifications & Engineering Support

Choosing the right sandwich panel load span is essential for structural safety and project cost optimization.

Tseason provides:

- Complete load span tables

- Engineering calculation assistance

- Purlin spacing recommendations

- Customized panel specifications for local codes

📩 Contact Tseason to receive the full technical dataset or request a project-specific calculation.

Our engineering team is ready to support your design and procurement decisions.