Tseason Sandwich Panel Installation Guide: Roof and Wall Systems for Modern Construction

Introduction

In modern construction, the demand for energy-efficient, durable, and aesthetically appealing building systems continues to rise. Tseason, one of China’s leading manufacturers of PU sandwich panels and insulated wall systems, provides comprehensive solutions for industrial, commercial, and cold storage applications.

This sandwich panel installation guide is designed to help project engineers and buyers understand the technical aspects, handling procedures, and installation methods for Tseason roof and wall panels. Whether you’re building a cleanroom, a cold storage facility, or a modular industrial building, this guide provides the essential information for achieving optimal performance, long service life, and a flawless architectural finish.

1. Understanding Tseason Sandwich Panels

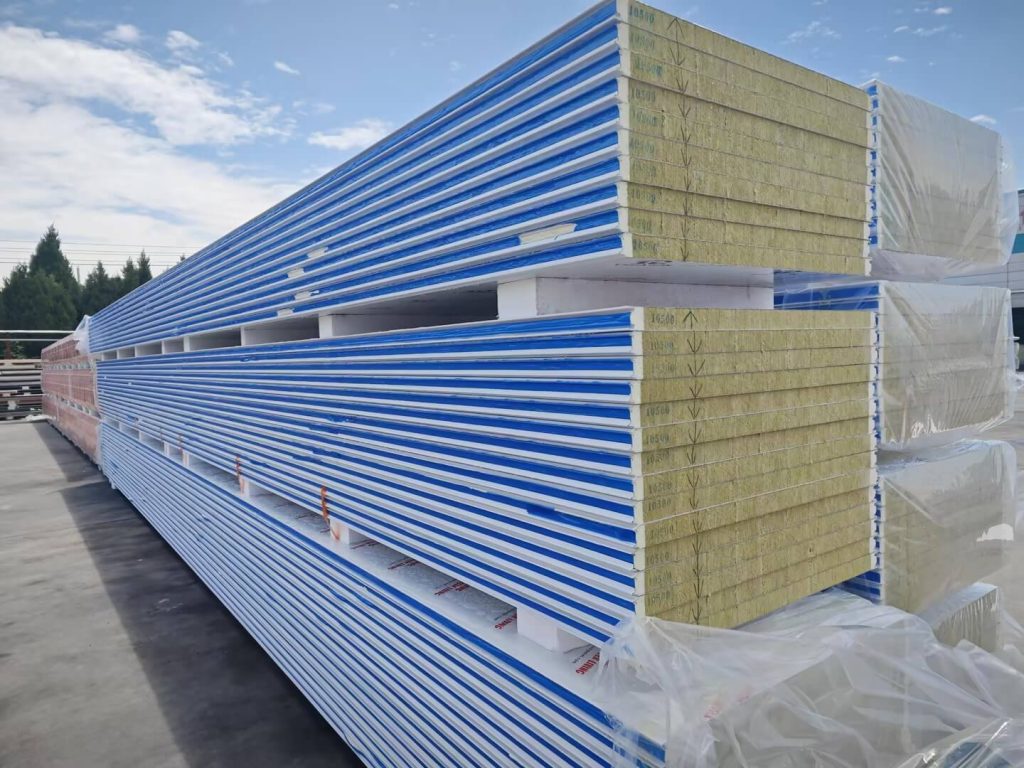

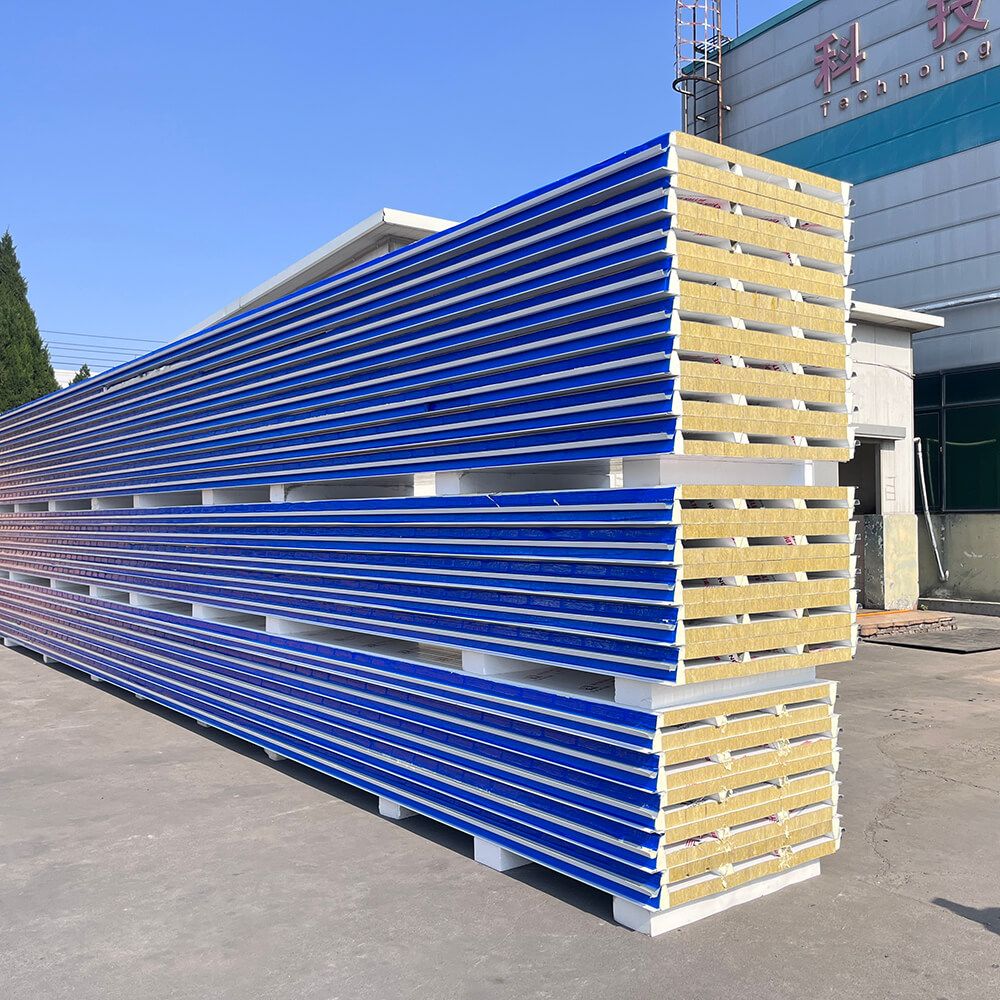

Tseason’s insulated roof and wall panels are advanced composite systems made from high-quality color-coated steel sheets and a rigid polyurethane (PU) or PIR foam core. This combination ensures superior insulation, high load-bearing capacity, and structural stability while reducing installation time and energy consumption.

Key Benefits

- Thermal Efficiency: PU core ensures low thermal conductivity and excellent energy conservation.

- Fire Resistance: Panels meet B1 fire rating, providing enhanced safety without compromising insulation.

- Durability: Metal facings are coated with PVDF or HDP for exceptional corrosion and weather resistance.

- Precision Manufacturing: Tseason panels are produced using advanced OMS and PUMA high-pressure foaming machines, ensuring uniform density and consistent adhesion.

- Quick Installation: Modular tongue-and-groove or concealed fixing systems simplify assembly, reducing labor costs and project time.

Applications

- Industrial and commercial buildings

- Cold storage and logistics centers

- Cleanrooms and food processing areas

- Prefabricated and modular construction projects

2. Pre-Installation Preparation

Proper preparation is critical for a smooth and efficient installation process. Before handling Tseason sandwich panels, ensure that the following steps are taken.

2.1 Site Inspection and Planning

- Verify the foundation’s alignment and load-bearing capacity.

- Confirm that the steel structure or support frame complies with engineering drawings.

- Check all anchor points and ensure the surfaces are free from dust, oil, or moisture.

- Designate a safe area for unloading and temporary storage of panels.

2.2 Handling and Storage

Tseason panels must be handled with care to maintain surface integrity.

- Use nylon straps or padded slings during unloading. Avoid metal chains or hooks that could damage panel edges.

- Store panels horizontally on flat ground or wooden pallets.

- Keep packaging intact until installation begins.

- Cover panels with waterproof sheets if stored outdoors.

- Avoid stacking panels too high (maximum 1.2 meters per stack).

2.3 Tools and Equipment

Ensure availability of the following tools:

- Electric screwdrivers or drills with torque control

- Leveling tools (spirit level or laser level)

- PU foam sealant gun and sealant materials

- Lifting devices with suction pads for large panels

- Cutting tools (only when trimming is necessary; always protect the steel coating)

3. Wall Panel Installation Guide

Depending on architectural and functional requirements, Tseason wall sandwich panels are designed for vertical or horizontal installation.

3.1 Alignment and Base Fixing

- Confirm the base channel is straight and level before placing the first panel.

- Use galvanized steel base channels or aluminum profiles as per design.

- Fix the channel using expansion bolts at intervals of 400–600 mm.

- Apply a layer of PU sealant along the channel to prevent air and moisture leakage.

3.2 Panel Installation Steps

- Positioning the First Panel:

- Align vertically using a level tool.

- Secure temporarily with clamps to maintain position.

- Joining Panels:

- Fit the tongue-and-groove joint precisely.

- Apply PU sealant inside the groove before inserting the next panel.

- Tighten the concealed screws (self-tapping type) along the joint line.

- Sealing and Finishing:

- Apply additional sealant to external joints to prevent air or water infiltration.

- Clean excess sealant with a soft cloth immediately after installation.

- Use Tseason aluminum flashings to cover corners, edges, and junctions for an aesthetic and watertight finish.

3.3 Recommended Fastening Spacing

- Vertical walls: 300–400 mm spacing between screws

- Horizontal walls: 400–500 mm spacing, depending on wind load

- Corner sections: Add extra screws within 100 mm from the edges

4. Roof Panel Installation Guide

Tseason insulated roof panels feature overlapping or concealed fastener designs, offering superior weather resistance and a clean appearance.

4.1 Preparation

- According to the panel load chart, verify roof purlins are level and properly spaced.

- Ensure safety harnesses, scaffolding, and lifting equipment are properly installed.

4.2 Installation Sequence

- Starting Point:

Begin from the leeward side (opposite prevailing wind direction). - Fixing:

- Overlap the side ribs by at least one full wave to ensure water tightness.

- Use self-drilling screws with neoprene washers to fasten panels to purlins.

- Joint Sealing:

- Apply a continuous bead of butyl sealant between overlaps.

- Check for uniform compression of the sealant after fixing.

- Ridge and Eave Treatment:

- Use Tseason’s custom ridge caps and drip flashings to ensure no water ingress.

- Maintain a slope of at least 5° for effective drainage.

4.3 Roof Safety Tips

- Avoid stepping directly on panel ribs to prevent deformation.

- Do not drag panels across the surface. Always lift and place carefully.

- Remove metal debris or filings immediately to avoid corrosion spots.

5. Corner, Joint, and Finishing Details

5.1 Internal and External Corners

Tseason provides prefabricated corner trims that ensure perfect alignment and consistent sealing performance.

- Internal corners: Use matching PVC or aluminum angles, sealed with PU foam and silicone.

- External corners: Apply L-shaped aluminum profiles for enhanced aesthetics and protection.

5.2 Ceiling Junctions

For cold room or cleanroom projects, ceiling junctions require special sealing:

- Apply closed-cell foam tape or silicone between ceiling and wall junctions.

- Fix aluminum cover strips to achieve airtight and hygienic joints.

5.3 Flashings and Accessories

All flashings are made from the same color-coated steel material as the panels.

Tseason offers standard accessories, including:

- Corner trims

- Door and window frames

- Drip caps and ridge flashings

- Silicone sealant and PU foam kits

6. Installation Quality Check

Upon completion, inspect the entire installation for alignment, sealing, and structural integrity.

6.1 Visual Inspection

- Surfaces must be smooth and free from dents or scratches.

- Joints should be uniform and tightly sealed.

- Color consistency should be checked under daylight conditions.

6.2 Functional Inspection

- Verify there is no air leakage in cold storage or cleanroom applications.

- Conduct a water spray test on the roof panels to ensure zero leakage.

- Confirm that all fasteners are securely tightened and sealed.

7. Maintenance and Service

Tseason panels are engineered for low maintenance. However, regular checks ensure maximum service life and performance.

7.1 Cleaning

- Clean surface dust or stains with mild detergent and water.

- Avoid strong solvents or abrasive materials.

7.2 Repainting and Touch-Up

For minor scratches, use color-matched touch-up paint. Never use incompatible coatings.

7.3 Inspection Frequency

- Annual inspection for sealants, flashings, and fasteners.

- After extreme weather events, inspect roof joints and edges immediately.

8. Why Choose Tseason Panels

Advanced Production Equipment

Tseason operates fully automated production lines using Italian PUMA and German OMS foaming machines. These machines guarantee uniform foam density (40–42 kg/m³) and exceptional panel bonding strength.

Strict Quality Control

Each batch of panels undergoes comprehensive testing, including:

- Thermal conductivity measurement

- Adhesion strength test (≥0.1 MPa)

- Fire resistance certification (B1)

- Dimensional tolerance and surface flatness checks

Global Supply and Project Experience

Tseason panels are trusted by clients in more than 30 countries across Asia, the Middle East, and Europe. The company’s products have been widely used in:

- Food and pharmaceutical factories

- Cold storage logistics centers

- Modular prefab buildings

- Industrial cleanrooms

Environmental Commitment

Tseason is certified as a Henan Green Factory 2024 and adopts eco-friendly polyurethane formulations with low VOC emissions. The company’s continuous efforts in energy-efficient construction align with global sustainability goals.

9. Safety Precautions

- Always follow workplace safety standards and local building regulations.

- Wear personal protective equipment (helmet, gloves, harness).

- Do not use damaged panels or accessories.

- Avoid open flames near PU foam materials.

10. Conclusion

Installing Tseason insulated roof and wall panels correctly ensures superior building performance, long-term durability, and visual excellence. With advanced production technology, global quality certifications, and proven project experience, Tseason stands as your reliable sandwich panel supplier in China, offering complete technical support from design to installation.

Whether you are constructing a cold room, cleanroom, warehouse, or modular industrial facility, Tseason’s comprehensive range of PU sandwich panels delivers the perfect balance of performance, efficiency, and aesthetic value.

For project inquiries or technical consultation, contact Tseason today — your trusted partner for insulated sandwich panel solutions.